Company

About us

We started as a small section of Televés Corporación, producing reduced numbers of printed circuits to satisfy the company’s own demand for the design and manufacture of equipment and systems to provide homes, buildings and cities with optimum telecommunications infrastructures.

Over the years GCE has evolved into a market leader in technology, valued for its vast experience and ongoing innovation.

We are a leading company in the market thanks to our experience, striving for the continuous improvement of our production processes and our commitment to latest-generation technologies but, above all, because we believe in what we do and how we do it, with client satisfaction always at the forefront.

Our staff currently comprises 35 highly qualified professionals who are the cornerstone of our organisation.

Our unequivocal values are technology development, quality, flexibility, product reliability, commitment, trust, forging close relationship with our clients and meeting delivery times. That’s why our daily mission is to endeavour to give our best, offering the best service that contributes to the success of our clients.

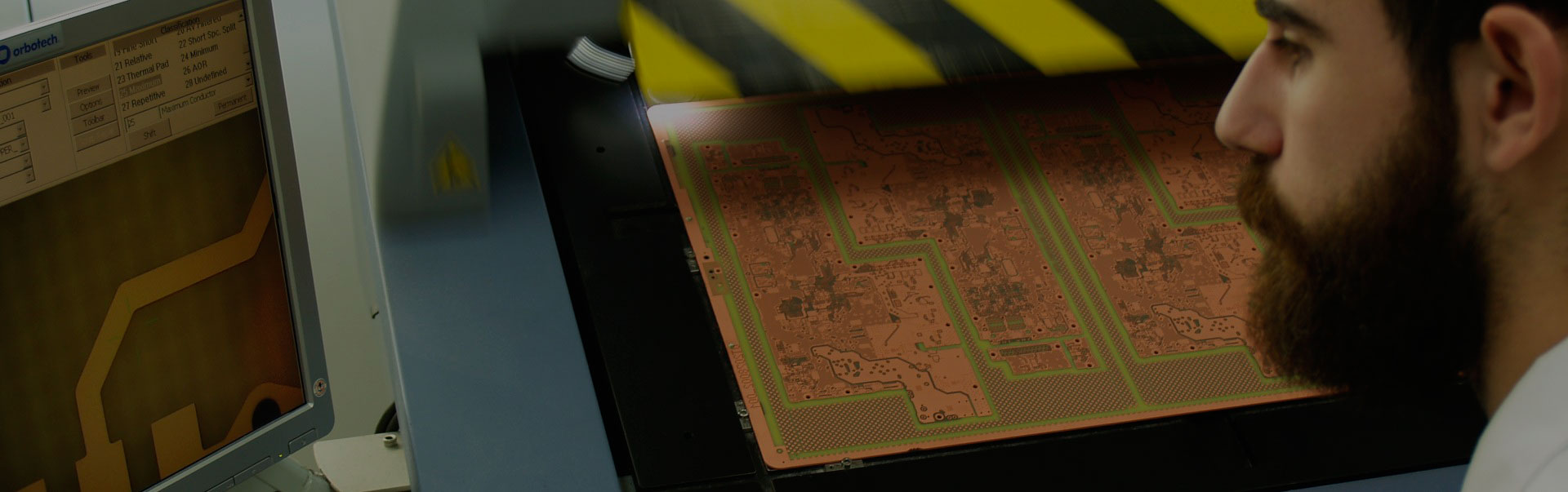

Technology

Gallega de Circuitos Electrónicos, S.L. has the latest printed circuit manufacturing technology so we can offer the best quality at competitive prices. We can offer the most demanding circuits, even with large-scale production.

Belonging to a great technological-industrial group means we can provide the added value of offering our clients all the resources and facilities of Televés Corporación that each project requires. These resources include:

- Design equipment.

- CNC machines for drilling and milling.

- Polisher for brushing and cleaning panels.

- Class 100 cleanroom with all machinery for the lamination and insolation process, guaranteeing clean conditions and environmental control.

- Chemical lines for all processes required for the manufacture of printed circuits:

- Development line.

- Black oxide line for internal layers.

- Single-side and multi-layer etching line.

- Double-side etching line.

- Electrolytic line.

- Desmear-DMS line.

- Micro attack line.

- Silver line.

- Ni-Au line.

- Robotic machines for optical product inspection (AOI).

- Laser repair station.

- Internal layer centering machine.

- Soldermask, insolation and curing line with laser PCB marking to ensure process traceability.

- Moving point circuit test machine with centering camera for final panel verification.

Quality

One of the cornerstones of our company’s policy is quality, therefore we have dedicated more time and resources to this activity over the years. The GCE Quality Management System is applied in accordance with UNE-EN-ISO 9001 requirements. This system involves all areas and personnel so we can obtain products according to the needs and specifications of our clients. We always bear the following principles in mind:

- Our activity always focuses on client satisfaction.

- All staff take part in achieving our objectives.

- All staff are involved in process control.

- Continuous improvement and innovation of our processes.

We also guarantee full product traceability, including a register of all information related to raw materials, test results, etc., so we can identify the product during the manufacturing process and after delivery.

Human Resources

Our team is our most valuable resource and it combines the most highly qualified technicians and the most experienced professionals.

Our ongoing training and knowledge management plans allow us to remain at the forefront of technology, while optimising our resources and guaranteeing the highest quality standards.

Therefore, GCE offers clients the best professionals to complete their technology projects.

Sectors

The purpose of Gallega de Circuits Electrónicos, S.L. is to research, develop, design, manufacture and market printed circuits. To achieve this, the sales department works with very diverse sectors:

- Telecommunications.

- General electronics.

- Car industry.

- Building (smart building control, energy control, etc.).

- Security (video entry systems, alarms, etc.).

- Lifts.

- Refrigeration.

- Lighting (cars, signs, homes, industries, etc.).

- Radofrequency.

- Recreation.

- Vending.

We can work with this wide variety of sectors thanks to our competitiveness, guaranteed quality, competitive pricing, and our excellence client service.

Innovation projects

Call for subsidies/grants from the Galician Energy Institute for energy saving(s) and efficiency projects in the industrial and services sectors. Year 2021-2022

Name of subsidized projects:

PRESS REPLACEMENT FOR MULTILAYER PRINTED CIRCUITS

(File nº: IN417Y-21A0140)

Energy saving and efficiency projects in Galician companies for the year 2023-2024, co-financed by the European Regional Development Fund under the FEDER-Galicia 2021-2027 Operational Program

![]()

PLASMA TREATMENT SYSTEM FOR PRINTED CIRCUITS

(File nº.: IN417Y-23A56)